Revolutionizing Industry: Retrofitting Existing Equipment with Smart Sensors

In the fast-paced world of industry, the race for efficiency, productivity, and innovation never stops. As technology continues to advance, businesses are continually seeking ways to optimize their operations without the heavy burden of investing in entirely new equipment. Enter the game-changing concept of retrofitting existing machinery with smart sensors. This transformative approach not only breathes new life into old equipment but also propels companies into the era of Industry 4.0.

What is Retrofitting?

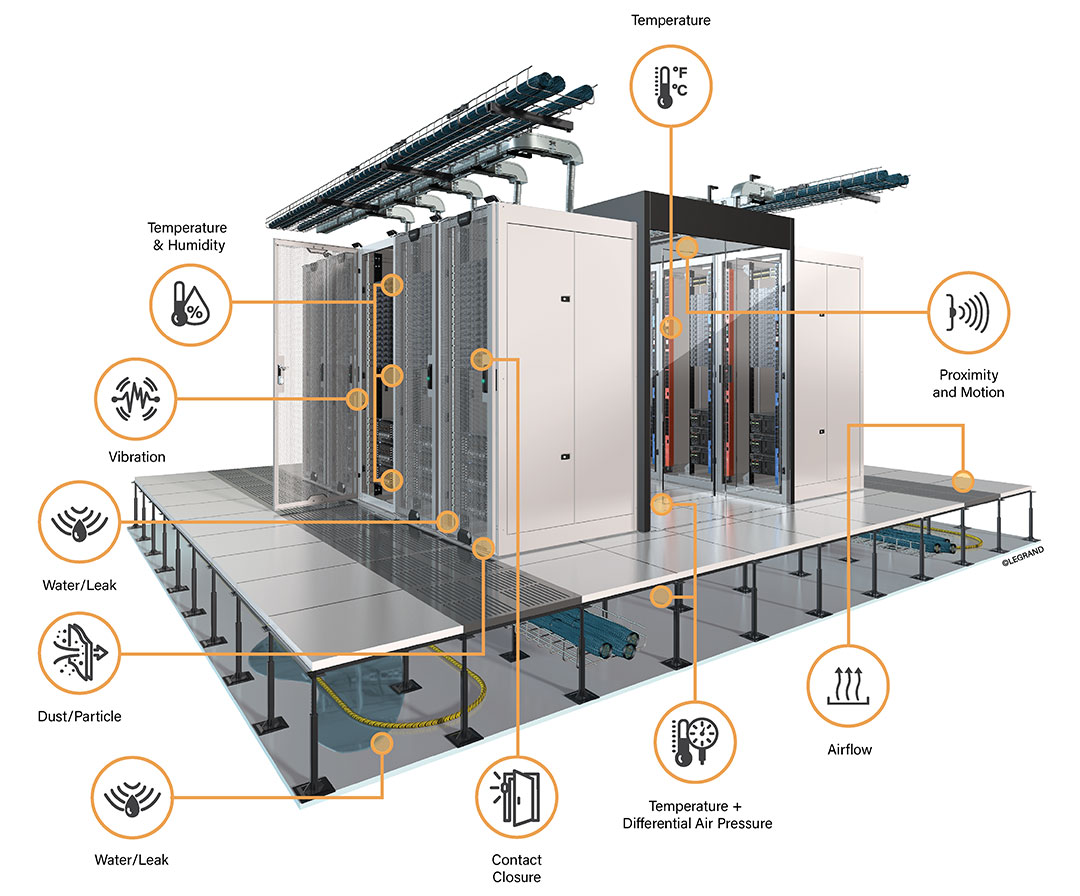

Retrofitting involves upgrading existing machinery with modern components and technologies to enhance performance and functionality. When we talk about retrofitting with smart sensors, we refer to equipping legacy equipment with advanced sensors that monitor various parameters in real time, such as temperature, pressure, vibration, and more. This integration opens the door to a wealth of data that can drive better decision-making and operational efficiency.

Why Retrofitting with Smart Sensors Makes Sense

1. Cost-Effective Upgrades

Investing in new machinery can be prohibitively expensive, especially for small and medium-sized enterprises. Retrofitting existing equipment with smart sensors offers a budget-friendly alternative. By enhancing what you already have, you can achieve significant improvements in efficiency and performance without the capital outlay required for brand-new machines.

2. Extended Equipment Lifespan

Every piece of machinery has a finite lifespan, and as equipment ages, its performance may decline. By retrofitting with smart sensors, you can monitor the health of your machines in real time, allowing you to identify potential issues before they lead to costly breakdowns. This proactive approach not only extends the life of your equipment but also reduces maintenance costs over time.

3. Data-Driven Insights

The true power of smart sensors lies in their ability to gather and analyze data. Once integrated, these sensors provide valuable insights into your operations. Imagine having the ability to monitor performance metrics, detect anomalies, and even predict maintenance needs. With this data at your fingertips, you can make informed decisions that enhance productivity and streamline processes..

4. Enhanced Safety and Compliance

Safety is paramount in any industrial setting. Smart sensors can help ensure a safer work environment by monitoring critical parameters and alerting operators to potential hazards. Furthermore, they can assist in maintaining compliance with industry regulations by providing accurate data for reporting and audits.

The Retrofitting Process: What to Expect

1. Assessment and Planning

The first step in the retrofitting journey is a thorough assessment of your existing equipment. This involves understanding your current processes, identifying areas for improvement, and determining which sensors will be most beneficial for your operations. Our team collaborates with you to create a tailored retrofitting plan that aligns with your goals.

2. Selecting the Right Sensors

With a plethora of smart sensors available on the market, choosing the right ones can feel overwhelming. Factors such as compatibility, data requirements, and the specific metrics you wish to monitor will guide the selection process. Our experts help you navigate these choices to ensure optimal integration with your machinery.

3. Integration and Testing

Once the sensors are selected, the integration process begins. This may involve installing sensors, connecting them to a central monitoring system, and calibrating them for accuracy. Testing is a crucial part of this phase to ensure that the sensors are functioning correctly and providing reliable data.

4. Monitoring and Optimization

After the retrofitting process is complete, it’s time to put your new smart sensors to work! Continuous monitoring allows you to track performance metrics in real time, enabling you to make adjustments as needed. Over time, this data can reveal trends that help you optimize processes further.

Success Stories: Real-World Impact

Many companies have experienced significant benefits from retrofitting their equipment with smart sensors. For example, a manufacturing plant that implemented smart sensors to monitor machine vibrations saw a 30% reduction in downtime due to predictive maintenance. Another facility reported a 20% increase in overall efficiency by utilizing real-time data to streamline production processes.

Conclusion

Retrofitting existing equipment with smart sensors is a powerful strategy for organizations looking to stay competitive in today’s technology-driven landscape. By enhancing your current machinery, you not only save on costs but also unlock a wealth of data that can transform your operations. Embrace the future of industrial innovation, and give your legacy equipment a new lease on life. If you’re ready to explore how retrofitting can benefit your business, contact us today to start your journey toward smarter, more efficient operations!